Full Foil Drive™ Motor RefurbishmentUpdated a month ago

All toys in a marine environment need some love periodically to keep them in tip top shape and ready to provide hours more fun out on the water. If you're noticing some knicks, scratches or some surface corrosion starting to form on any part of your motor, this article will show you how you can do some very simple cleaning and painting to ensure your gear is well protected from the harsh marine environment we are using it in.

Note: If you are not comfortable or willing to do this maintenance yourself, please contact your local Foil Drive™ Dealer, authorised repair centre or contact us directly at [email protected] to arrange for this work to be done for you. Alternatively, all spare and replacement parts are available at www.foildrive.com.

Note: You will need to have an account on our Foil Drive™ website to gain access to the repairs section on our website. Click here to learn how.

If you are interested to learn more about the Foil Drive™ motor design and features, have a watch of the Tech Talk Video with Paul and Ben.

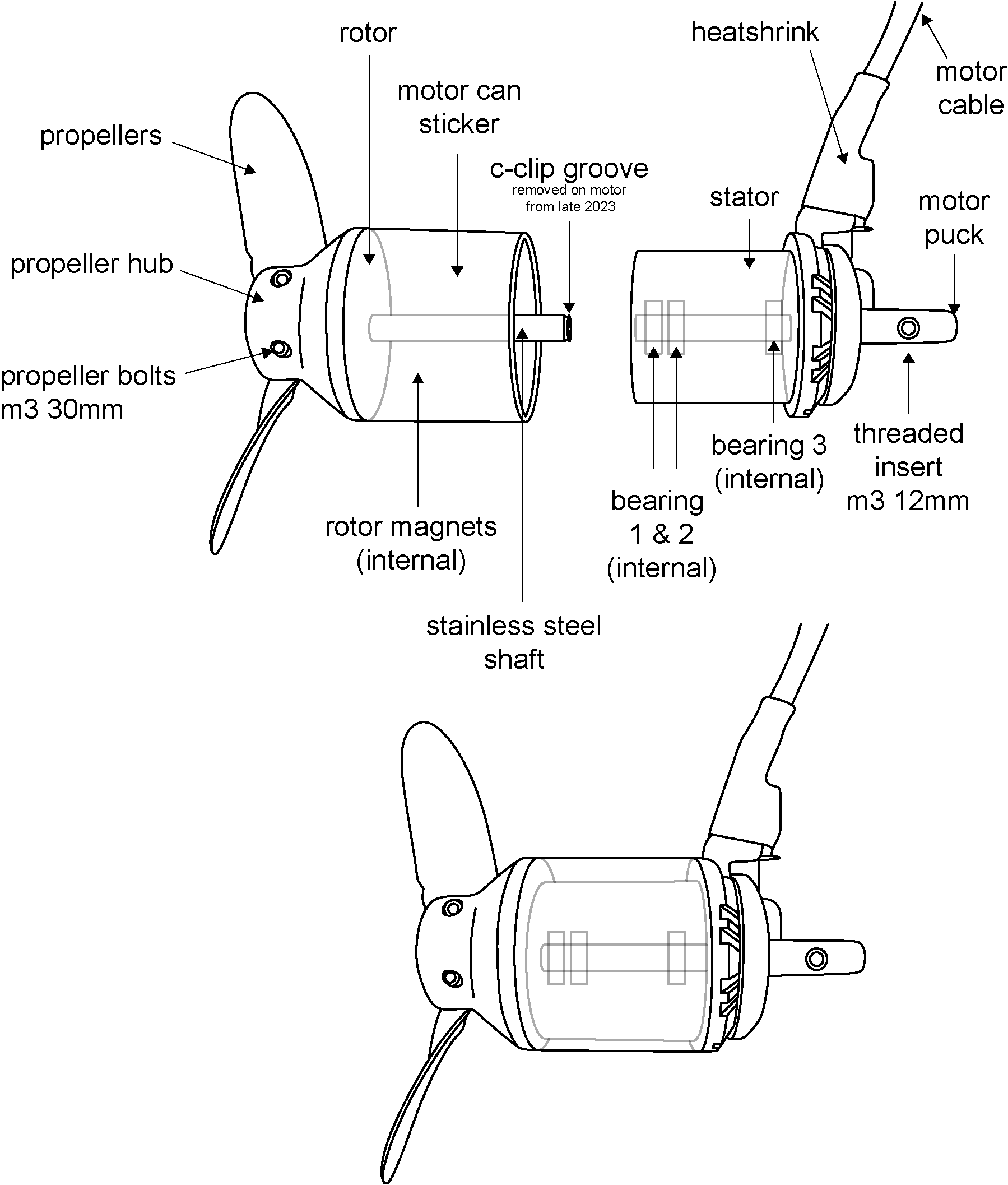

Below is a detailed diagram of the parts of your Foil Drive™ motor. In this video series, you will be working with both the rotor and the stator.

You will need:

- Motor with circlip removed and outer spinning Rotor removed. Click here to see our article/video on removing the circlip (FD kits prior to 2023) and separating the rotor from the stator.

- Wet and dry sandpaper around 400grit and 120grit (not super important exactly which grit you use)

- Isopropyl cleaning alcohol or similar cleaning agent.

- Paper towel or clean rags

- Painter's masking tape

- Replacement motor can sticker

- Good Quality Black Rust Preventative Epoxy Enamel Spray Paint for Metal Surfaces

- 2.5mm Foil Drive™ hex driver

* For our customers in the US, you can use this or similar as a lubricant for your rotor and stator- Lubricant/Corrosion Inhibitor (It can also be purchased at Home Depot). For Australian Customers, you can use a WD40 Lanolin Based Rust Preventor.

Repainting the External Surface of the Motor Can/Rotor

- Remove the propellers and hub from your motor.

- You can use your motor pod attached to your mast as a stand or mount the motor to your bench.

- Remove the old sticker from the rotor.

- With your wet & dry sandpaper, remove the surface corrosion and paint back to bare metal. Note: We use the Foil Drive™ system to spin the motor at a medium speed RPM during this process.

- Once the rotor is back to bare metal and smooth, use a cleaning solvent like isopropyl alcohol to ensure the surface is completely clean.

- Mask up and protect all areas of the motor to protect it from paint over-spray.

- Run the motor slowly and apply a very thin, light coat of paint to the rotor.

- Repeat the light coating of paint 3-4 times until a smooth consistent paint coating is achieved.

- Once the paint is completely dry, apply a new replacement motor can sticker to further protect the paint when out in the water.

Repainting the Internal Surface & Magnets of the Rotor

- Remove the rotor from your stator.

- Consider the condition of the magnets inside the rotor. If it is simply missing paint and there is some light surface corrosion, a refurbishment is recommended. If there is significant material loss to the magnets, we can supply a cost-effective replacement rotor.

- Use a small strip of sandpaper and two fingers to sand back any loose debris, surface corrosion and paint until the rotor is back to bare magnet material. Note: Using water with wet and dry sandpaper can help keep the sandpaper clean as you go.

- Use fresh water and a clean rag to wipe over the surface. Then again with isopropyl cleaning alcohol to completely clean and dry out the internal surfaces ready for paint.

- Use masking tape to mask up the external surfaces of the motor from overspray.

- It is incredibly important that you also mask up the entire motor shaft from top to bottom to protect from overspray of paint. Any paint on the motor shaft will not allow the shaft to pass through the ceramic bearings. Note: In the video we have used a small syringe outer tube to cover the motor shaft.

- Using thin, light misting coats of the epoxy enamel, paint the internal surfaces of the rotor. Do not spray too much paint at one time as this will cause the paint to run or pool in the bottom of the can.

- Take your time and do two or three coats coming at it from both left and right sides of each magnet to ensure a complete coverage.

- Wait for the paint to be completely dry (at least a day to cure) before re-installing the rotor onto the stator.

Repainting Motor Stator

- Remove the rotor from the motor and set aside.

- Clean the stator with isopropyl cleaning alcohol.

- Use wet and dry sandpaper to remove any section of surface corrosion and ensure the whole stator is a smooth surface. Note: There is no need to take this part back to bare metal.

- Check for any exposed copper wiring. The copper you can see is still coated and being exposed won't cause any issues, however, you can use marine Sikaflex to cover it up. Follow the steps in this article to cover exposed copper wiring.

- Clean the stator once again with alcohol to ensure a clean surface ready for paint.

- It is very important to mask up the ceramic bearings in either end of the motor to protect from over spray. Note: Any paint on the bearing will affect its performance significantly and can even ruin the bearing entirely. Also mask up the aluminium base of the stator as this does not need to be painted.

- Use the epoxy enamel paint in 3 or 4 very light, consistent coats to achieve complete coverage of the stator.

- Wait until the paint is completely dry before reassembling the rotor back onto the stator.

For more information about ongoing regular servicing and cleaning after every use, see our article on cleaning and after use care to improve the longevity of your motor.

Related Articles - Click to read:

Foil Drive Rotor Refurbishment

Replacing and Securing Ceramic Bearings on Foil Drive Motor

Fixing Exposed Copper Wiring on Foil Drive Stator

Foil Drive Motor Design | Universal

To learn more, check out the other articles on our Help Centre which can be found under the 'Support' tab on the website.

As always, if you have any questions, please reach out to us at [email protected].

Happy Foil Driving!