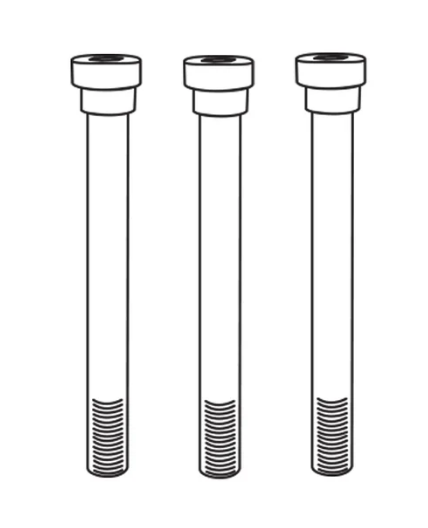

Three Blade Propeller BoltsUpdated 16 days ago

An update for Foil Drive customers using Three Blade Propellers with an introduction to our NEW bolt design and tips on how to maximise your setup.

After identifying some areas for improvement, we're excited to bring you an update regarding the Three Blade Propellers including information on how to fine tune your existing hubs as well as an introduction to our NEW custom Foil Drive Stainless Steel Bolt Design.

These bolts feature a custom shoulder and have individually been CNC machined to shape specifically for Foil Drive Hubs.

You can purchase the new design bolts here

Highlights:

- Custom CNC machined bolt, made specifically for our hubs

- Maximises strength

- Minimise risk of breakages by ensure your propellers can flop in and out easily.

- If your blades are sticking, back off the bolts by half a turn, including the bolt on top of the three-blade hub

- Bolts can also be used on two blade hubs, with some minor modifications

To learn more, watch the video below

00:00 Introduction

01:02 New Hardware - Introduction

02:50 Cause and Effect - Hub Damage

03:33 Solutions - Propeller Bolt Tension

04:19 Solution - Centre Bolt Tension

05:35 Solution - Ridge Removal

06:09 New Hardware Upgrade - Overview

06:29 Two Blade Hubs - Installation

07:45 New Hardware - Comparison

Related Articles -

Foil Drive Motor Vibrating

Choosing Motor Cable Length

Full Foil Drive Motor Refurbishment

To learn more, check out the other articles on our Help Centre which can be found under the 'Support' tab on the website.

As always, if you have any questions, please reach out to us at [email protected].

Happy Foil Driving!